Profile of Goghnath Industries

Goghnath Industries is one of the prominent precision fabricator in Gujarat at Ahmeadaba established and growth with the goal to being the leader in the world of Sheet Metal Components and Fabrication.

Goghnath Industries laser cutting department is capable of handling every metal cutting services. From thin materials to thick materials, our laser cutting machine can handle it all. With a high-peak pulse feature, the device can provide dross-free cutting on metals from copper to brass to aluminum and others. Our laser cutting and etching tools also make it possible for us to cut grooves or pockets that only extend partly through the metal.

We are having the state of the art infrastructure where we have all well known company machines as well as experienced staffs which are providing their service for outputting your quality work with the way of excellence. We have growth our business by adopting the latest, extraordinary and advanced technology at Goghnath Industries.

Company Information

| Nature of Business | Exporter, Manufacturer and Service Provider |

| Company CEO | Mr. Mangalbhai Patel |

| Registered Address |

C-12, Shayona Estate, Memco Cross Road, Naroda Road, Ahmedabad - 380 025 Gujarat, INDIA |

| Services |

Manufacturing Exporter Of Stainless Steel Fabrications Aluminium Fabrications Precision CNC Laser Cutting Sheet Metal Fabrication Laser Cutting Services CNC Bending Work VMC and CNC Machining Drilling Tapping Welding Services Etc |

| Total Number of Employees | 20 to 25 People |

| Year of Establishment | 1994 |

| Legal Status of Firm | Proprietorship Firm |

| Promoter | Mr. Mangalbhai Patel |

| Annual Turnover | Rs. 5 - 7 Crore (INR) |

| Top Export Countries | Qatar, Canada and other 4-5 Countries. |

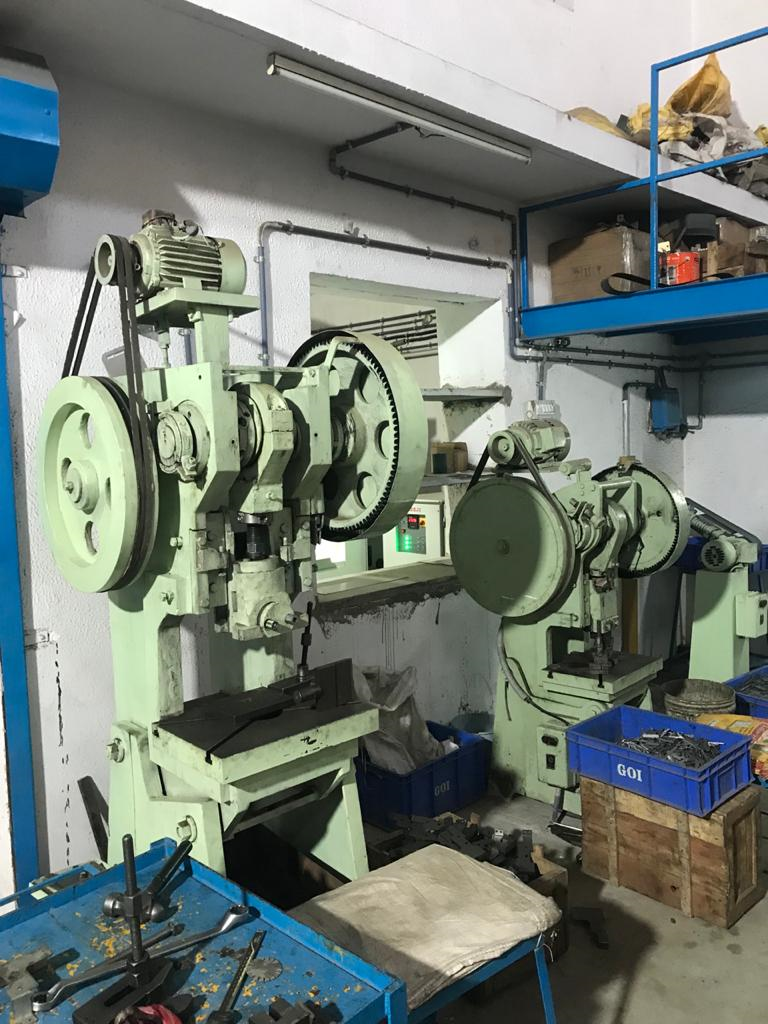

Infrastructure

| Location Type | URBAN |

| Building Infrastructure | Permanent |

| Size of Premises | 1200+ square yard Workspace |

| No. Of Laser Cutting Machine | 3 |

| No. Of VMC Machine - VF2 (HAAS) | 1 |

| No. Of Bending and Roll Bending Machine | 2 |

| Size Of Mechanical Power Press | 5 Tones to 100 Tones - 14 Nos. |

| Other Infrastructure |

Electric Welding Stud Welding Spot Welding Mig Welding(250 AMP, 450 AMP) Tapping Attachment Drill Machine Lathe Machine (5.5 Feet Length - 6 Nos) |

| Godown for Prepared Item and Raw Materials | Available |

Company USP

| Primary Competitive Advantage |

• Experienced R & D Department • Good Financial Position & TQM • Large Production Capacity • Provide Customized Solutions |

| Quality Measures / Testing Facilities | Available |

| Certification for Process | ISO 9001:2008 - Euro Cert |

| Company Registration | Registered in 1994 as Proprietorship Firm Under Government of India. |

| Production Capacity | 2 to 3 Tones per day (Approx) |

Statutory Profile

| Import Export Code (IEC) | 08110XXXXX |

| Tan No. | AHMM0XXXXX |

| Banker | BANK OF BARODA |

| GST No. | 24ABJPP8119M1Z6 |

Packaging, Payment and Shipment Details

| Customized Packaging | Yes - As per Your Requirement |

| Payment Mode |

• Cash • Cheque • DD • Bank Transfer – NEFT / RTGS / IMPS • Wire Transfer • Paypal and Other Platform |

| Shipment Mode |

• By Road • By Air • By Train • By Ship |

Our Commitment

Our first responsibility is to provide our Customer with exceptional value for the commitment they have made to our company. We achieve this goal by providing the utmost in Customer service.

Our Vision

Under the observation and superior guidance of our Technical Engineer, Mr. Gamerbhai M. Patel, we have created a benchmark in the competitive industry. His vast technical skills and vast practical experience help us in providing quality products and services to our clients. Moreover, owing to our timely delivery services, quality conscious approach with technical knowledge, we have established cordial business relationship with our esteemed clients. Our vision is to maintain, expand and multiply the business relations for long lasting.

Our Mission

We have always achieved an extra ordinary growth and became successful, is a result of our dedication and efficiency of service to the industry. Our company works with a philosophy of centralization for customer focus, customer approach and customer satisfaction.

Specialised In

We have always achieved an extra ordinary growth and became successful, is a result of our dedication and efficiency of service to the industry. Our company works with a philosophy of centralization for customer focus, customer approach and customer satisfaction.

At Our Workshop

Our highly qualified employees carry out processing for you on modern CNC machines and equipment. This ensures consistent high-quality work. In addition, the overall solution, consisting of the enclosure and customer-specific processing, results in faster delivery times while reducing the risk of both rejects and unexpected transport costs.

Please contact us for more details or quotation. Contact Us